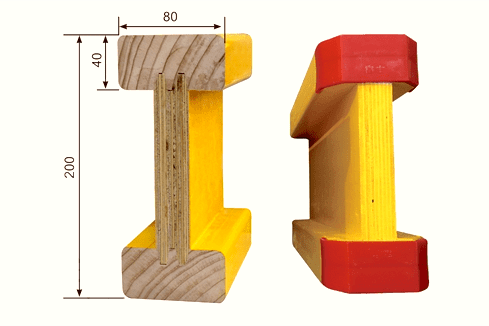

H20 Beam

H20 Beam is a very important part of the formwork system and has been widely applied in construction.

As required, standard holes can be drilled in the two ends of timber beams. We can lengthen the timber beam by end-to-end joint. According to customers’ demand, we can produce timber beams of any length.

Different Types of H20 Beam For You to Choose

H20 Beam

Without Cap

H20 Beam

With Plastic Cap

H20 Beam

With Steel Cap

H20 Beam

With End-to-End Joint

Description Of APAC H20 Beam

- Raw Material: Pine or Spruce or others

- Glue: Waterproof Phenolic WBP

- Density: 5.0-6.0 kg/m

- Wood Humidity: 12%±2%

- Painting: Yellow Waterproof Painting or as per request

- Length: 1.3/1.45/1.95/2.45/2.65/2.90/3.30/3.60/3.90/4.50/4.90/5.90m or customized length

- Delivery time: 15-30 days

- Package: Pallet

More Details About APAC H20 Beam

Quality Control

We have QC teams for inspection such as moisture control, glue inspection both before production and after production, material grade selection, pressing checking, and thickness checking.

Surface Treatment

Moisture and mold-resistant coating. Three layers of paint, are more conducive to waterproofing. The specially designed rolling mechanism for easy pallet loading and unloading.

Perfect Packaging

Covered with waterproof shrinking film& craft paper, bundle with steel stripes outside. And then packing in pallets, 150pcs/ pallet, or special logistic packing according to customer request.

Factory Direct Wood Beam with Competitive Price

APAC is a factory-direct manufacturer, we can make sure that give you the best price with high-quality H20 Beam for your projects.

- Easy handling and quick assembly.

- High load capacity, recovery capacity after application of load.

- Good ratio between price and use.

- Can be used many times.

-1024x283.png)