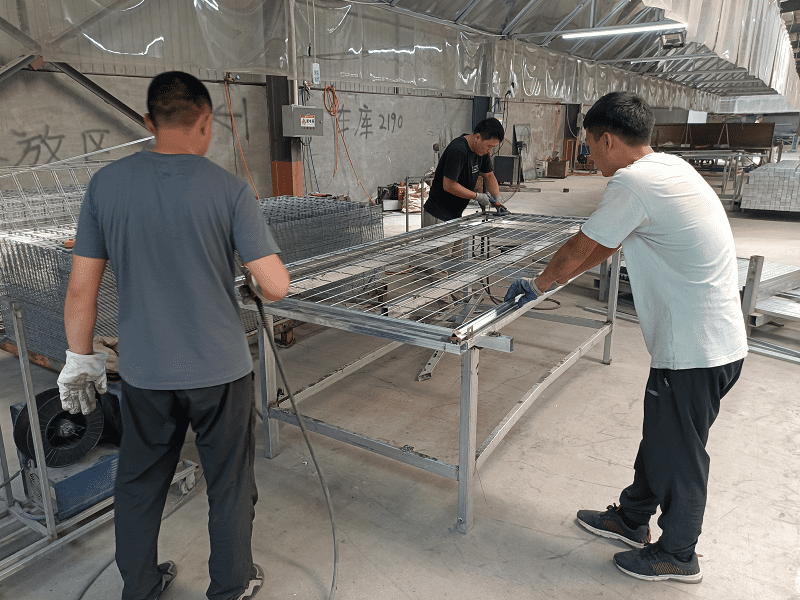

Strong Factory Stand by Your Side

As a technical manufacturer, high-quality standards are upheld throughout our entire manufacturing process.

Design → Raw material inspection → Sampling → Mechanical processing → Welding → Surface treatment → Inspection → Packing.

Every design and finished product is done in-house by our experienced technical team. The high-quality edge protection systems make your worksite safer in resonate with your project needs in different application scenarios.

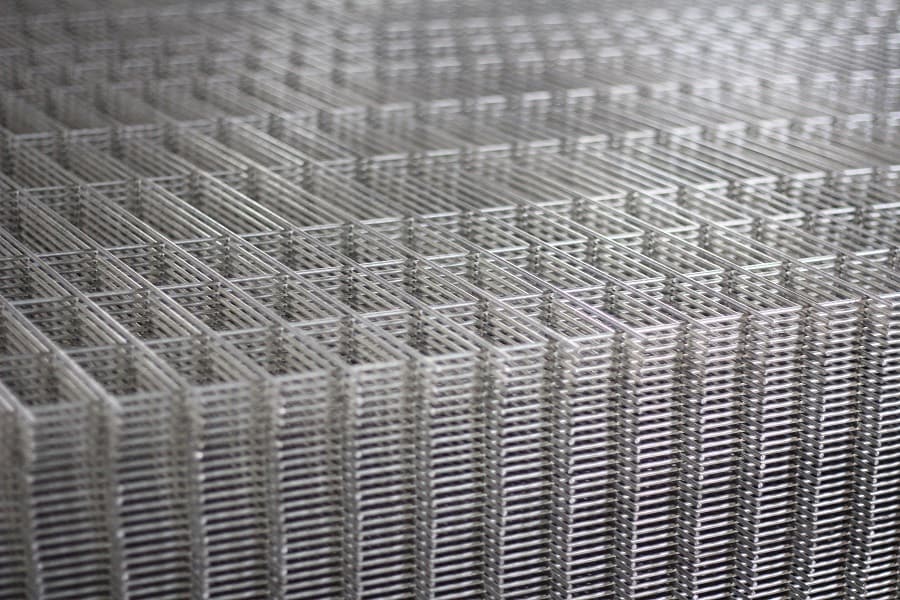

Quality from the Ground Up: Our High-Quality Steel Materials Make a Difference

By selecting these high-quality Q235 and Q345 steel materials, we can ensure that our products are built to last.

Our Automated Cutting Process Sets Us Apart

Automated cutting is a critical part of our manufacturing process at the factory. We ensure that our products are accurately and efficiently cut to the exact specifications required for each project.

Expert Welding Ensures the Durability of Your Products

We use a variety of welding methods to suit the needs of each project, including MIG, TIG, and Laser welding, our team of skilled welders are trained in the latest welding techniques.

Surface Treatment For You To Choose

Surface treatment is a critical part of our manufacturing process at the factory. We use various methods to ensure that every product we build is strong and durable.

One of the most effective methods we use is hot-dip galvanizing, which involves immersing metal parts in a bath of molten zinc. This creates a durable, long-lasting coating that protects the metal from rust and other forms of corrosion.

Another effective method we use is powder coating, which involves applying a dry powder to the surface of the metal, then heating it to create a durable, long-lasting finish. Powder coating is available in a wide range of colors and finishes, allowing us to customize the appearance of our products to suit our client's needs.

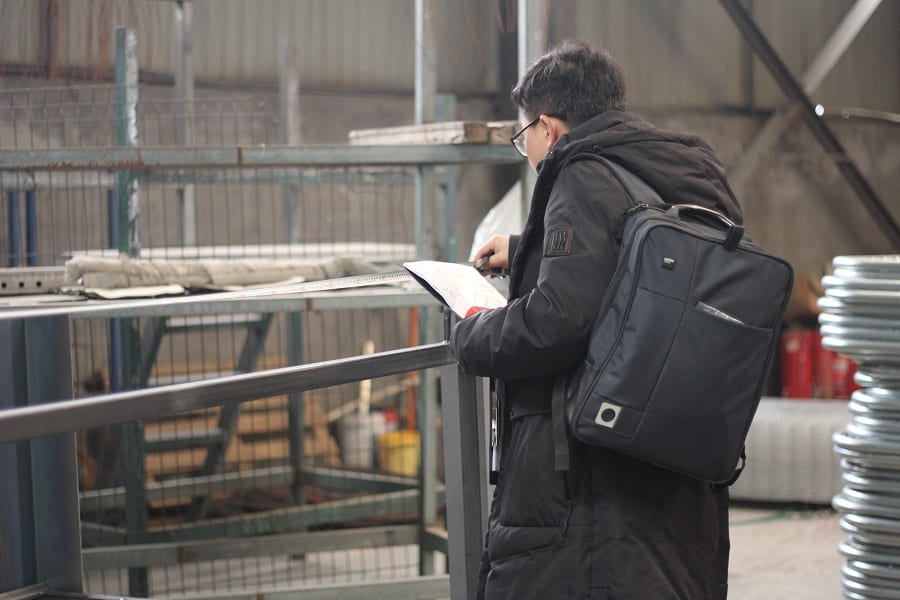

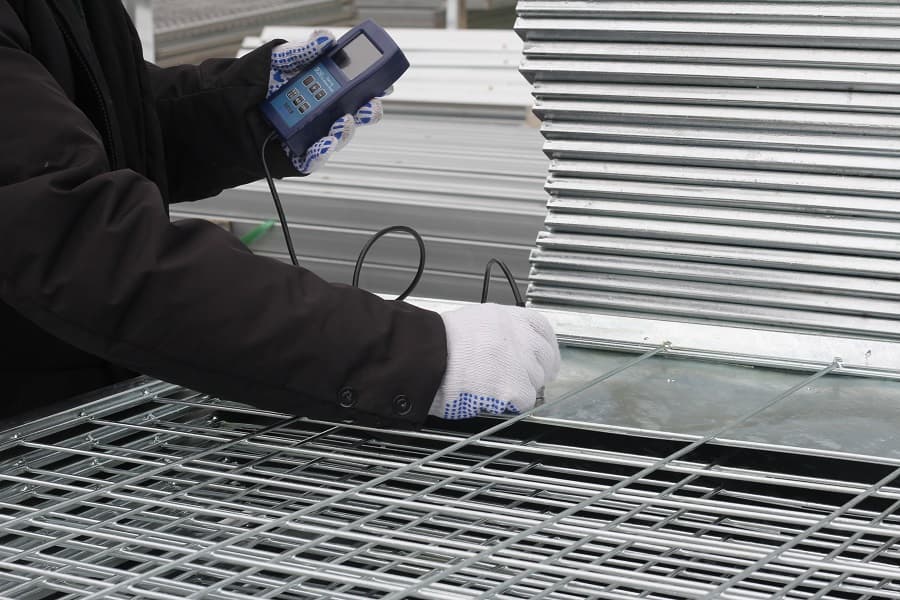

Quality First Manufacturing

Throughout the manufacturing process, we use a variety of testing and inspection techniques to ensure that each product meets our stringent quality standards. This includes visual inspections, dimensional measurements, and material testing, among other methods.

We also maintain strict documentation procedures, tracking every aspect of the manufacturing process and maintaining detailed records of all inspections and tests.

Quality Packaging in the Manufacturing Process

We use a variety of packaging materials and techniques depending on the size, shape, and weight of the product. For smaller items, we use custom-designed boxes and inserts to protect against damage during shipping. For larger items, we use pallets and crates to provide maximum stability and protection.

Convenient and Cost-Effective One-Stop Service

Responding to all your edge protection needs, every procedure, from material to ship to your door, we practice excellence to ensure our products will surpass your expectations.

- Professional Technical Team

- Consistent Quality

- Custom ODM Solutions

- Large Order Discount

- Years of Expertise

- Efficiency Response

- Profitable OEM Services

- Timely After-sale Service