Exemplary Edge Protection Systems:

Our Unwavering Focus on Quality

We take great pride in producing high-quality edge protection systems. Our uncompromising commitment to quality is reflected in every aspect of our production process, from the selection of materials to the final inspection of finished products. We understand the importance of safety and reliability in edge protection systems, and we go above and beyond to ensure that our products meet and exceed industry standards. Our goal is to provide our customers with the peace of mind that comes with knowing they are using the very best edge protection systems available.

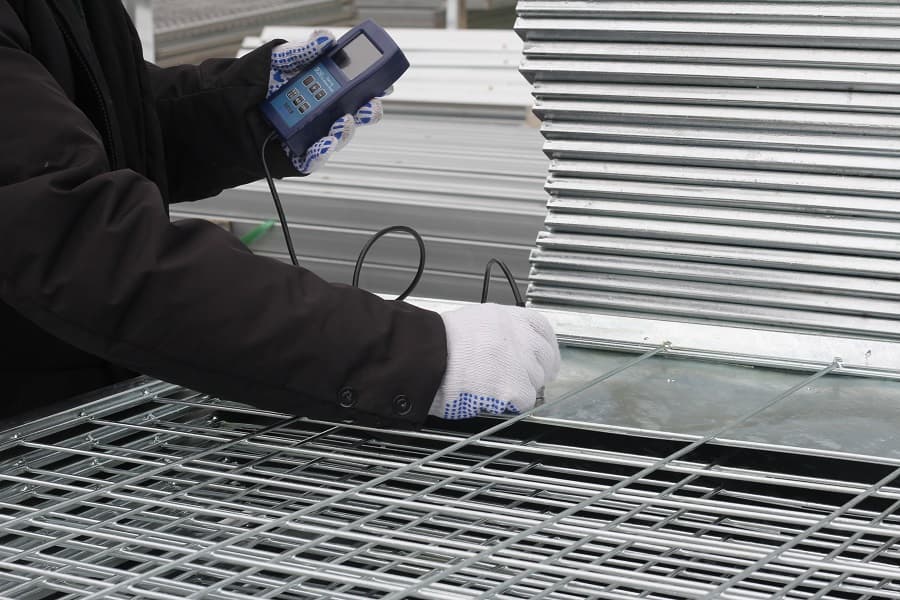

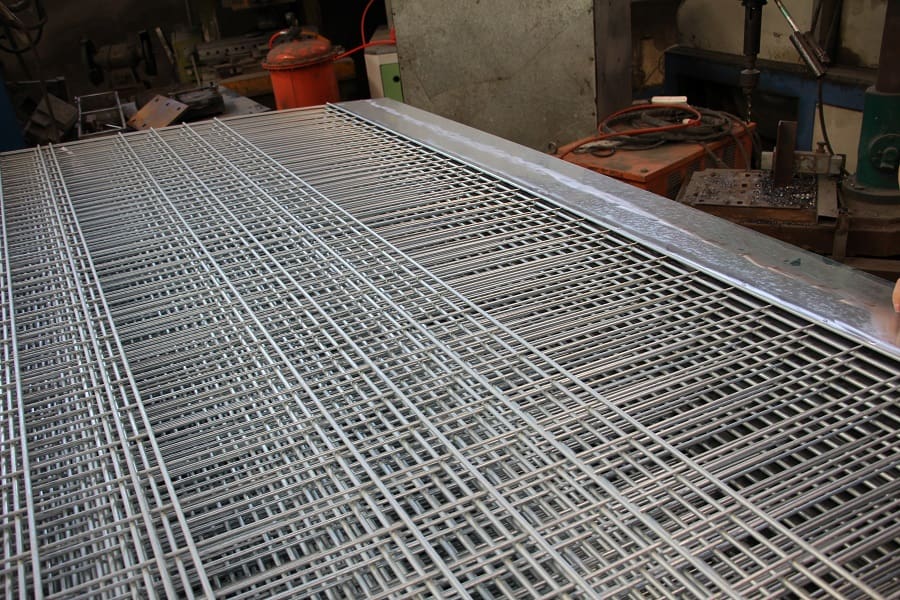

During Production

In addition to inspecting raw materials, we maintain a vigilant eye on the production process to ensure both quality and timely delivery of our edge protection systems. Our dedicated team closely monitors each step of manufacturing to guarantee that our rigorous quality standards are met throughout production.

After Production

At the culmination of our production process, we conduct a comprehensive final check to guarantee the satisfactory quality of our edge protection systems. This final check ensures that all specifications, dimensions, and performance attributes align with our customers' requirements and industry benchmarks. By conducting this thorough examination, we affirm that our edge protection systems are of the highest quality before they leave our facility. This commitment to quality assurance is a testament to our dedication to delivering reliable and top-notch products to our valued customers.

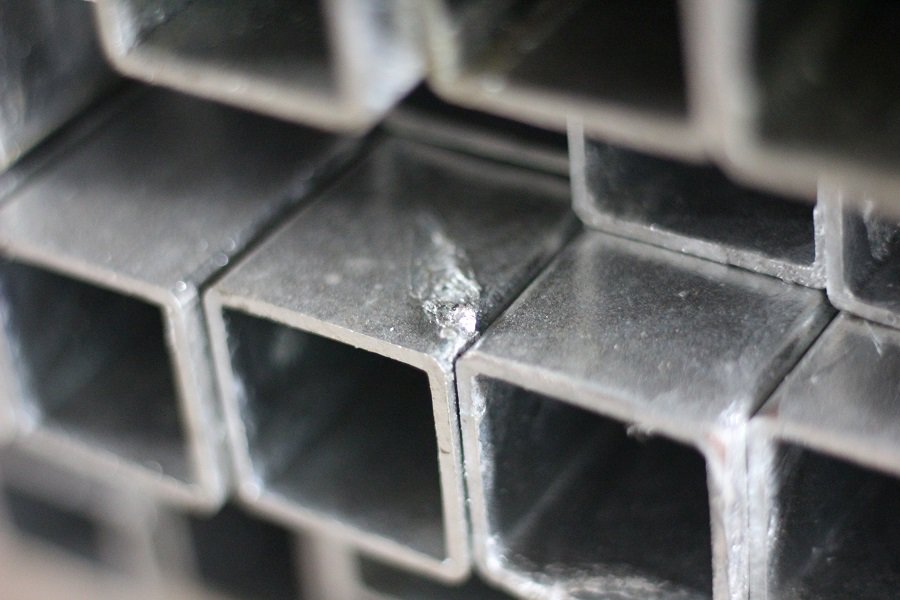

Unqualified Example

If our quality inspectors identify products that do not meet specifications, they promptly set them aside, ensuring they do not return to the production line until necessary rectification has been completed. Our quality inspectors adhere rigorously to quality inspection standards to ensure that every product meets high-quality requirements.

When issues are identified during quality inspections, we develop corrective action plans and issue reports to analyze and address the root causes of the quality problems. This includes tracing all production processes and stages, identifying factors that may contribute to the issues, and implementing appropriate corrective actions to eliminate potential quality risks.

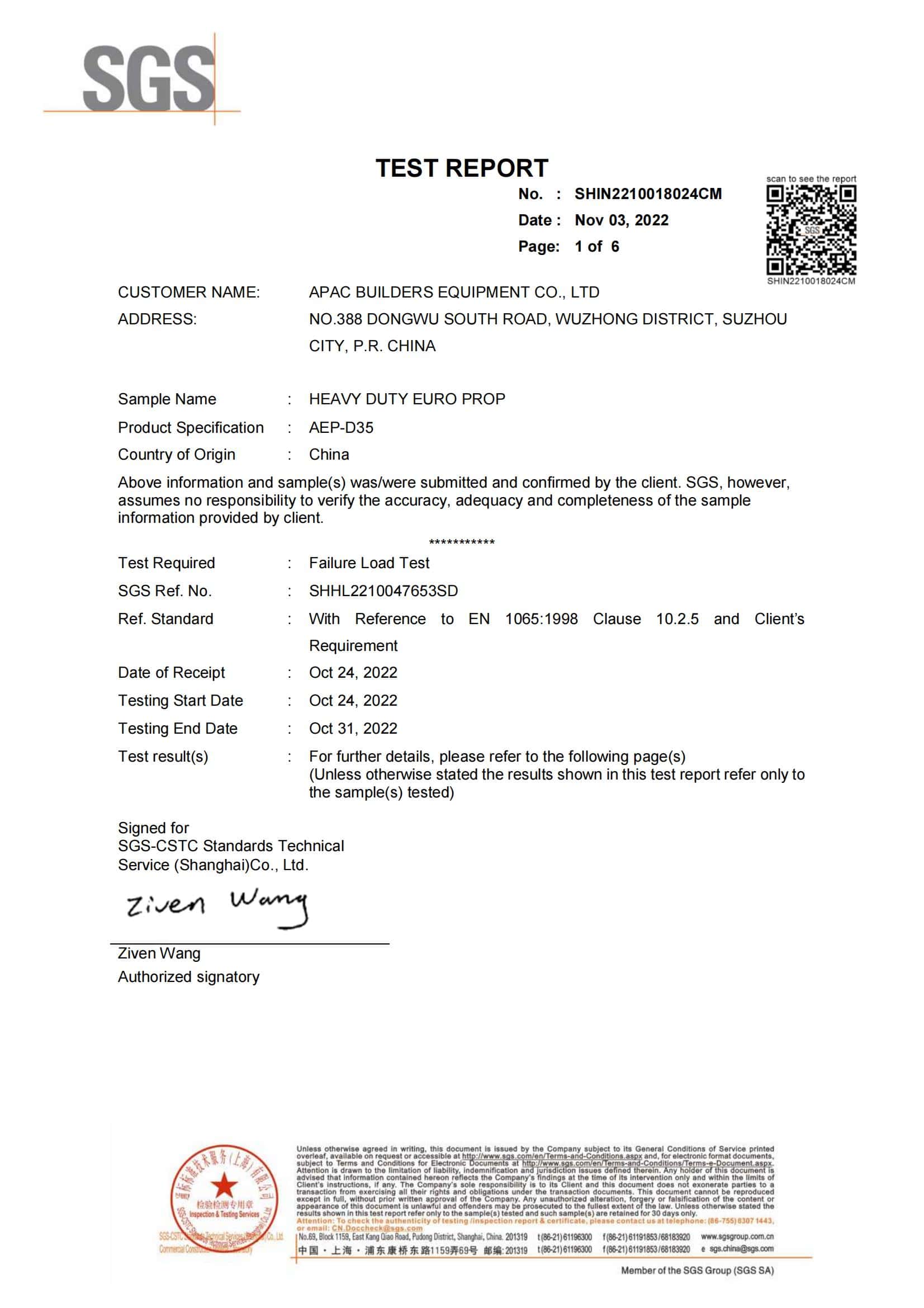

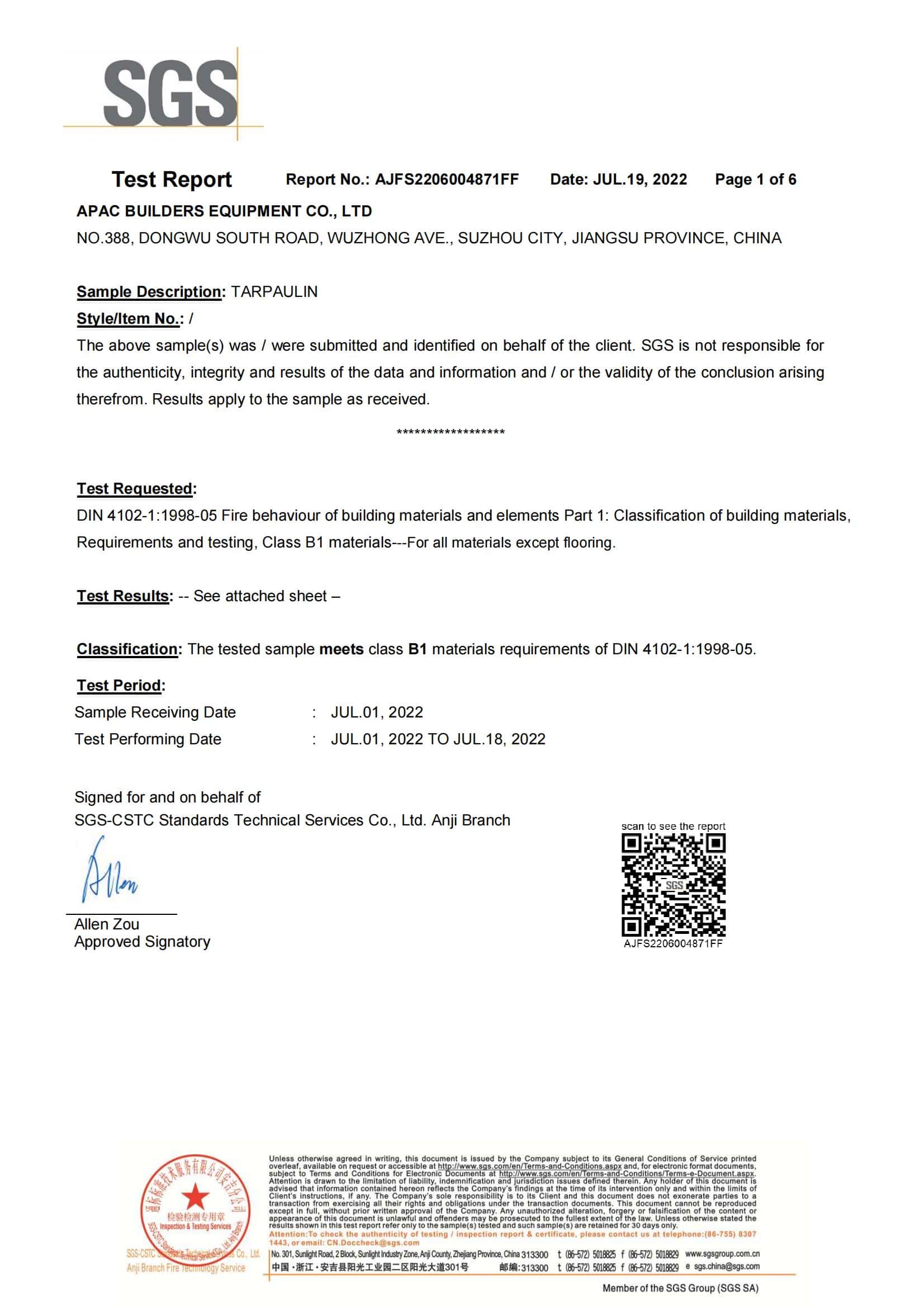

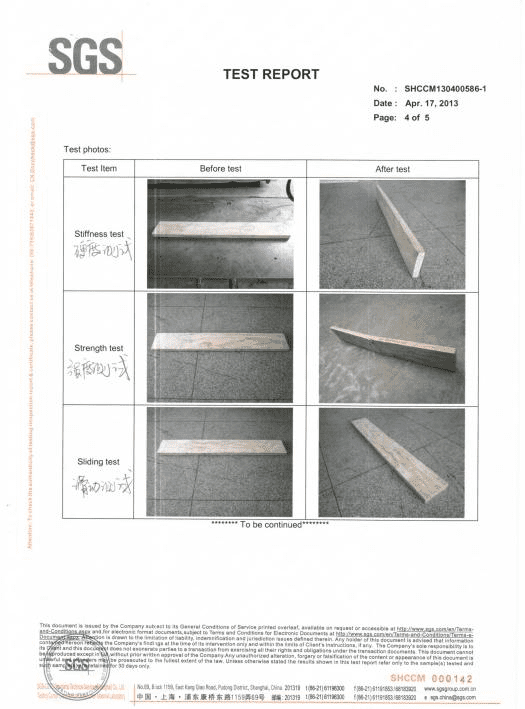

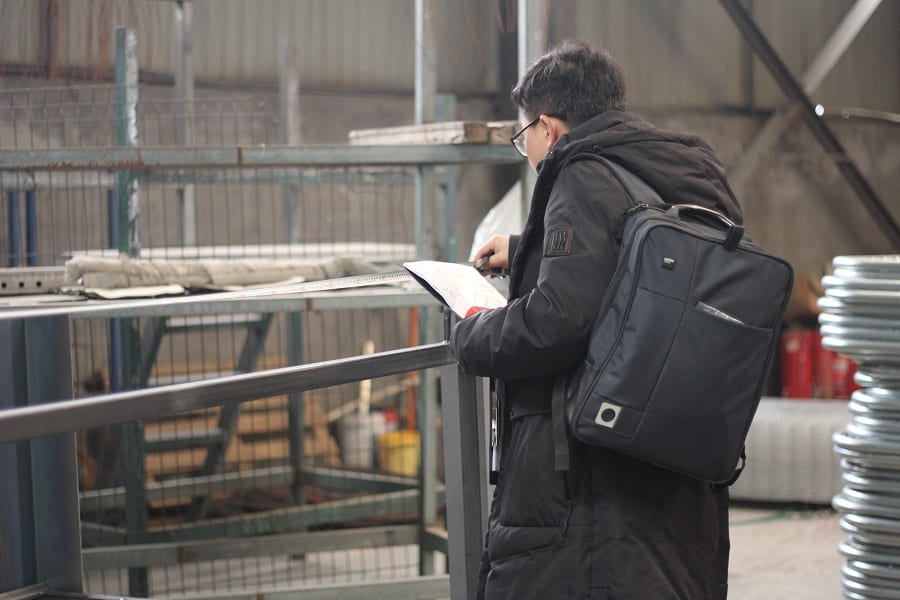

Tripartite Testing

In addition to our internal quality control measures, we also support and encourage third-party testing for our products.

By collaborating with reputable third-party testing laboratories or certification organizations, we can obtain unbiased evaluations of our products.